In the fast-paced world of global manufacturing, precision is the new currency. A missed defect, an undetected dimensional error, or an overlooked misalignment can cost manufacturers dearly—not just in terms of money, but also reputation.

This is especially critical for components like fasteners, shafts, and turned parts that demand 100% inspection from every possible angle. That’s where ACURA ROTARY 360, an advanced vision inspection system by Automation Artisans, comes into play.

Designed to offer 360-degree visual inspection at high speeds, this system is setting new standards in defect detection and dimensional gauging—transforming quality control across industries.

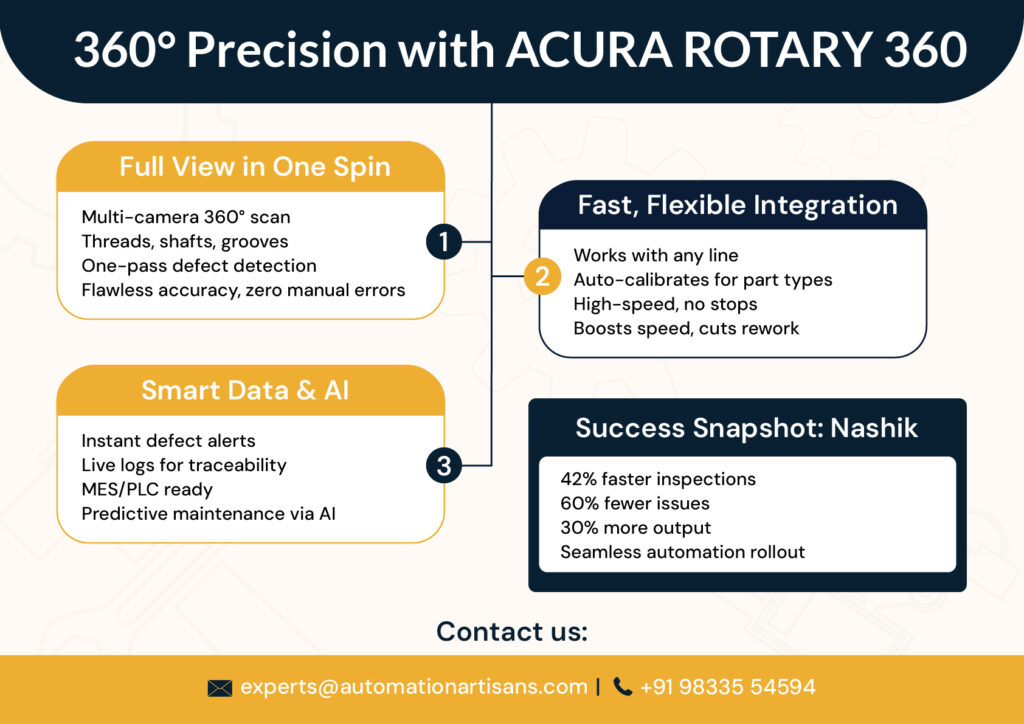

1. All-Angle Accuracy: Inspecting Every Detail in One Rotation

Unlike conventional systems that check only one or two sides of a component, ACURA ROTARY 360 utilizes multiple high-resolution cameras to deliver comprehensive 360° coverage in a single spin. This is especially critical for precision turned components, where surface finish, threading, and concentricity must be flawless.

The system’s rotary platform ensures seamless image stitching and real-time processing, making it ideal for:

- Threads and groove inspection

- Diameter and concentricity checks

- Shaft inspection system for manufacturing

- Common types of bolt inspection

With Automation Artisans’ proprietary algorithms, you get fast, consistent, and repeatable results—eliminating manual errors and ensuring zero-defect output.

2. Integrated Automation: Beyond Just Vision

ACURA ROTARY 360 isn’t just a camera system—it’s an intelligent automation company product that fits into any industrial automation and control systems setup. From small batch processing to continuous flow assembly lines, it offers seamless plug-and-play integration.

Manufacturers can expect:

- Custom machine vision solutions in India

- High-speed inspection without production halts

- Flexible system calibration for diverse part geometries

It’s not only the best machine vision system for quality inspection in terms of performance—it’s also built to adapt with minimal intervention, making it ideal for evolving production needs.

Real-time stat: Companies using rotary vision systems report up to 35% reduction in rework rates and a 50% increase in inspection throughput.

3. Built for Modern Manufacturing: Data, Decisions, and Speed

Today’s industrial automation companies don’t just inspect—they analyze. ACURA ROTARY 360 enables real-time data capture, analytics, and reporting, making it an essential tool for data-driven manufacturing environments.

Paired with a PLC or MES, this system:

- Flags defects instantly

- Logs data for traceability

- Supports quality assurance automation

- Facilitates predictive maintenance via AI-based alerts

This makes it ideal not just for automated sorting machines for industrial use, but for creating a feedback loop that improves the advanced manufacturing process over time.

It’s especially relevant in the machine vision technology for automotive industry, where every nut, bolt, and washer must pass rigorous tests before hitting the road.

Real-World Impact: An Indian Success Story

A Tier-2 automotive component supplier in Nashik implemented ACURA ROTARY 360 for inspection of precision-turned shafts. Their results within the first three months were transformative:

- 42% reduction in manual inspection time

- 60% fewer customer complaints

- 30% increase in monthly production capacity

With turnkey solutions from Automation Artisans—including installation, training, and support—their shift to full automation was seamless.

Why Choose Automation Artisans?

As one of India’s most trusted machine manufacturing companies, Automation Artisans stands out not only for product innovation but also for customer service. Our innovative systems are designed with manufacturers in mind—scalable, modular, and built for the Indian industrial landscape.

We don’t just sell machines. We offer complete turnkey solutions, from automated sorting system using machine vision to full-floor automation strategies.

Conclusion: 360-Degree Inspection Is the Future—Be Part of It

In an era where defects are not an option, investing in technologies like ACURA ROTARY 360 is no longer a choice—it’s a necessity. Whether you are a growing machine manufacturer or a global OEM supplier, systems like these future-proof your production with speed, data, and unbeatable accuracy.

If you’re looking to scale, compete globally, and deliver world-class precision, it’s time to look at vision inspection systems as more than just a support tool—they’re your competitive edge.

Stay Ahead with Us

Follow Automation Artisans on Instagram and LinkedIn for updates on our systems, real-world case studies, and new launches.