In today’s competitive industrial environment, speed without precision is a liability. For manufacturers working with high volumes of precision turned components, every micron matters. As demand increases across automotive, aerospace, and hardware sectors, so does the need for high-efficiency sorting solutions.

Enter GRAVISORT—Automation Artisans’ revolutionary automated sorting machine for industrial use, designed to handle the toughest component inspection challenges with remarkable speed, accuracy, and consistency.

Manufactured in India, GRAVISORT reflects the best of localized engineering and global innovation, helping Indian manufacturers step confidently into the era of global manufacturing.

1. Engineered for Speed: High-Volume Sorting Made Easy

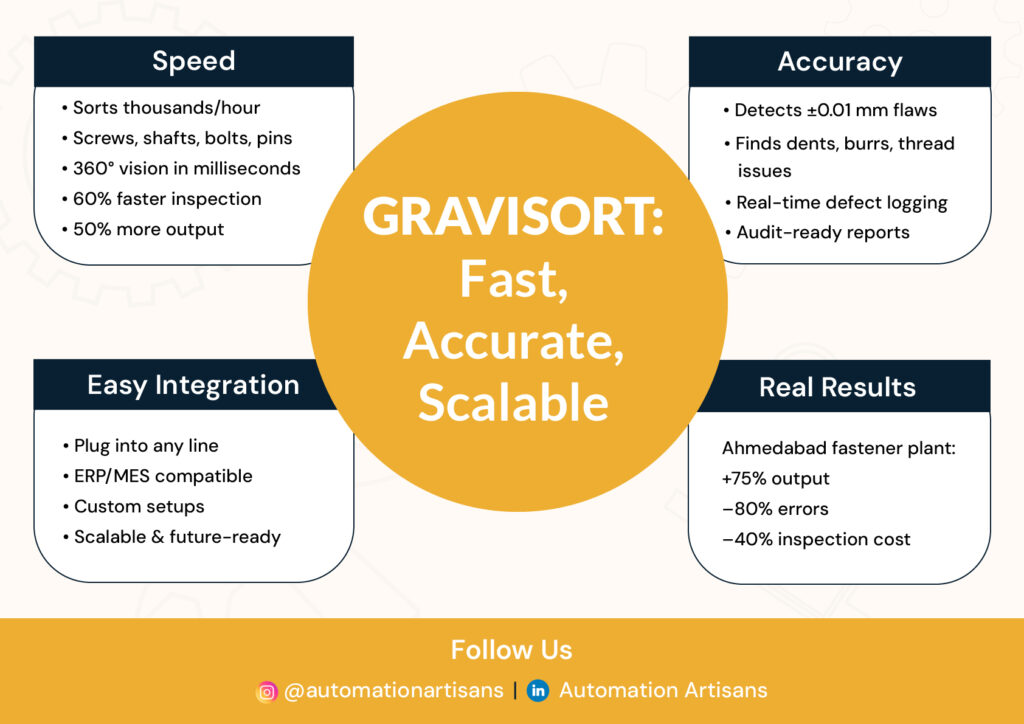

The hallmark of GRAVISORT is its unmatched throughput. Built for non-stop, high-speed sorting, it can process thousands of parts per hour—without sacrificing inspection accuracy. This makes it a vital asset for manufacturers dealing with:

- Screws, shafts, pins

- Common types of bolt inspection

- Cylindrical and symmetrical parts

Utilizing a vertical gravity-based part feed and advanced machine vision system, GRAVISORT ensures 360-degree evaluation for dimensional, surface, and geometric flaws.

Real-time stat: Factories using GRAVISORT have seen up to 60% reduction in inspection cycle time and 35–50% increase in daily output.

This level of performance makes it ideal for MSMEs and Tier 1 & 2 suppliers looking to upgrade from manual or semi-automated inspection setups.

2. Precision You Can Count On: No Compromise on Quality

While speed is important, quality assurance automation is what differentiates GRAVISORT from other solutions in the market. Equipped with the best machine vision system for quality inspection, the system can detect:

- Surface scratches, dents, and burrs

- Dimensional tolerances beyond ±0.01 mm

- Thread quality and concentricity issues

It’s especially impactful for shaft inspection system for manufacturing, where a single deviation can lead to machinery failures or rejected batches.

GRAVISORT also enables:

- Defect categorization (minor/major/critical)

- Real-time rejection tracking

- Seamless data reporting for audits and compliance

Built by one of India’s leading machine manufacturing companies, it brings the kind of consistency that human inspection simply cannot match.

3. Plug-and-Play Flexibility: A Future-Proof Solution for Indian Industry

GRAVISORT integrates effortlessly into existing production lines and industrial automation and control systems. It is scalable, modular, and compatible with ERP and MES systems for traceable inspection workflows.

This makes it a go-to turnkey solution for manufacturers who don’t want the headache of a complete line overhaul. Plus, with Automation Artisans’ custom machine vision solutions India, it can be tailored for your specific component type, industry norms, and output requirements.

In sectors like automotive, electronics, and hardware, where part variation is high, this kind of flexibility ensures future-readiness and operational efficiency.

Real-World Impact: A Gujarat-Based Success Story

A large-scale fastener manufacturer in Ahmedabad implemented GRAVISORT 2.0 for 100% inspection of M6 bolts. Within 90 days:

- Daily sorting capacity increased by 75%

- Manual error rate dropped by 80%

- Labour cost on inspection reduced by 40%

This allowed the client to accept new export orders while maintaining zero-defect delivery. It also helped them meet international compliance standards through robust inspection logs—a key factor for global manufacturing partnerships.

Built by Automation Artisans: Indian Innovation with Global Ambition

At Automation Artisans, we’re not just an automation company. We’re an innovation partner. From sorting machines like GRAVISORT to full-scale vision inspection systems, we deliver high-impact solutions tailored to Indian manufacturing needs.

We offer end-to-end services including:

- Feasibility testing

- Custom design

- System installation

- After-sales training & support

All part of our commitment to delivering innovative systems that help our clients compete on a global scale.

Stay Connected with Industry Innovation

Get the latest updates, use cases, and innovations from Automation Artisans.

Follow us on Instagram and LinkedIn** for behind-the-scenes stories, live installs, and tech updates.

Conclusion: Precision, Speed, and Scalability—All in One System

Manufacturing excellence in 2025 demands more than skilled labour and good raw materials. It demands smart systems that can scale, adapt, and perform without fail.

With GRAVISORT, Indian manufacturers now have access to a world-class automated sorting system using machine vision—right from an Indian-made, trusted partner.If you’re ready to take the next step in advanced manufacturing processes, it’s time to explore what GRAVISORT can do for your plant floor.