India’s manufacturing sector is entering a new era—one that blends precision with performance. From automotive components to fasteners and precision-turned parts, industrial automation companies are rapidly adopting innovative systems to keep up with global quality standards and productivity demands.

But what’s driving this transformation? The answer lies in advanced tech like machine vision systems, automated sorting machines, and AI-based turnkey solutions. These technologies are no longer a luxury—they’re becoming a necessity for manufacturers across India.

1. Vision-Driven Accuracy: Eliminating Human Error in Inspection

One of the key areas reshaping automation is machine vision technology for automotive industry and other sectors. Traditional inspection methods are not only time-consuming but also prone to inconsistencies.

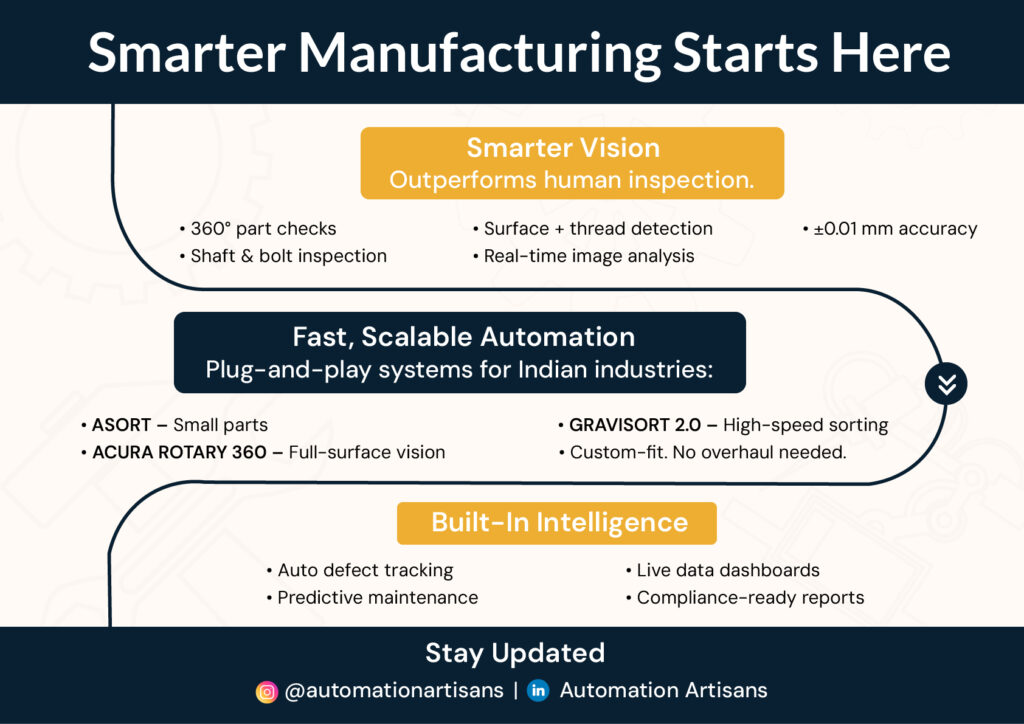

Machine vision systems like Automation Artisans’ ACURA and ACUSORT deliver unparalleled accuracy in dimensional checks, surface flaw detection, and quality assurance automation. These systems can identify even micron-level defects that the human eye may miss.

Real-time stat: The Indian machine vision system market is expected to grow at a CAGR of over 11% by 2028, driven by increased demand for error-free manufacturing.

2. Smart Sorting Systems: The Backbone of Speed & Scalability

High-speed production demands high-speed quality control—and that’s where automated sorting machines for industrial use shine. Systems like ASORT and GRAVISORT 2.0 bring automation to component categorization, helping manufacturers scale without compromising quality.

Whether it’s shaft inspection system for manufacturing, common types of bolt inspection, or complex turned components, these sorting machines categorize parts by visual cues, measurements, or defects with zero downtime.

Key Benefit: Automated systems work 24/7 without fatigue, making them a cost-effective solution for both MSMEs and large manufacturers.

3. Turnkey Solutions: Streamlining the Manufacturing Lifecycle

Gone are the days of sourcing different vendors for different parts of the automation journey. Indian machine manufacturing companies like Automation Artisans now offer turnkey solutions—complete with feasibility studies, customization, deployment, and ongoing support.

These industrial automation and control systems combine hardware and software into a seamless ecosystem. Plus, with plug-and-play capabilities, even complex installations can be completed in record time.

Custom Machine Vision Solutions India are now more accessible than ever, providing localized support, faster integration, and reduced costs for Indian businesses.

Real Use Case: Driving Global Manufacturing Standards

A Tier-1 auto parts supplier in Pune recently implemented Automation Artisans’ vision inspection system and sorting machine, resulting in:

- 30% reduction in production errors

- 50% faster defect detection

- 20% increase in monthly output

This is proof that adopting innovative systems not only future-proofs your business but directly impacts your bottom line.

Conclusion: The Time to Upgrade Is Now

Indian manufacturers can no longer rely on outdated manual systems if they aim to compete on a global manufacturing scale. Embracing advanced manufacturing processes powered by innovative systems is key to surviving—and thriving—in the new industrial landscape.

Whether you’re an MSME in Rajkot or a large-scale machine manufacturer in Chennai, integrating systems like vision inspection, automated sorting, and turnkey solutions is your fastest route to operational excellence.

Follow Automation Artisans on Instagram and LinkedIn for the latest updates on custom automation solutions, industry case studies, and product innovations.